The working principle of a film blowing machine

2023-05-27

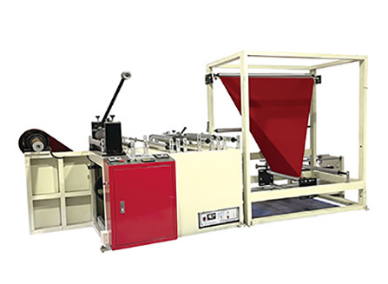

A film blowing machine is a piece of equipment used to produce plastic film and is one of the most commonly used machines in the processing of plastic products. It is widely used in the fields of packaging, building materials, medicine, agriculture and textiles. The working principle of a film blower is to extrude the plastic by melting the plastic and then extruding it. The plastic granules are heated in the die head and the airflow speed is manually or automatically controlled to pressurise the film into a multi-layer film.Cutting Bag Machine The working principle of a film blowing machine can be divided into the following processes: 1. Heating and melting of plastic pellets In the film blower cabinet, the plastic pellets are heated by adding a melting heater. The heater will heat the plastic pellets to a specific temperature and maintain a uniform temperature of the plastic. The heated plastic pellets become semi-liquid and become a malleable raw material.Bag Making Machine 2. Extrusion The dissolved plastic pellets are transferred to the screw of the extruder. As the screw rotates, the dissolved plastic pellets are pushed out to form a tube. When the tube reaches the right length, the machine automatically cuts it off.Bubble Bag Machine 3. Extrusion head The extrusion head is the part that does the work. As the tube passes through the extrusion head, the tube is stretched and filtered and then enters the air ring. The air ring is a circular part used to control the outer diameter of the tube. The air ring sends a large amount of high pressure air in to cool the outside of the tube. At this point the plastic has become a large flattened area. 4. Blowing the film In the blown film section near the air ring, air is blown into the bottom to form an air pack in a closed state at the top, which further expands the tubular. Through the combined action of the air ring and the blown film section, the plastic thins and eventually becomes film. 5. Winding Finally, the film is cooled and enters the winding section, where it is wound into coils or rolls. The winding section is usually available in automatic or manual winding options, depending on the specific requirements. In summary, the film blowing machine works by extruding the plastic in a molten state and then forming the plastic into a film product through the action of the airflow and the adjustment of the winding mechanism. Due to its good plasticity and malleability, the film blowing machine has become the obvious choice for many industries to carry out their business.